Best Banks with Mobile Check Deposit Guide

Discover the top-performing U.S. banks offering seamless mobile check deposits with our comprehensive guide to the best options for easy banking.

Discover the top-performing U.S. banks offering seamless mobile check deposits with our comprehensive guide to the best options for easy banking.

Find your step-by-step Guide to online bank account with instant debit card no deposit and enjoy quick, hassle-free setup. Get banking today!

Unlock savvy travel money tips with our guide to the cheapest way to get cash abroad, ensuring your funds stretch further on your adventures.

Discover the seamless process of transferring money with our Guide to Venmo to GCash, simplifying cross-platform transactions.

Explore your options with our guide to the best euro account in the UK. Find top-rated services for seamless currency management.

Discover the top destinations with our guide to best countries to open offshore bank account, ensuring privacy and financial benefits.

Learn the steps with our guide to how to receive money from Western Union in Kenya, ensuring quick, secure transactions.

Discover your ideal financial solution with our Guide to best free checking accounts, featuring top banks and no hidden fees. Your wallet will thank you!

Discover the essentials with our guide to how to open bank account online Kenya – seamless, quick & secure steps for your financial ease.

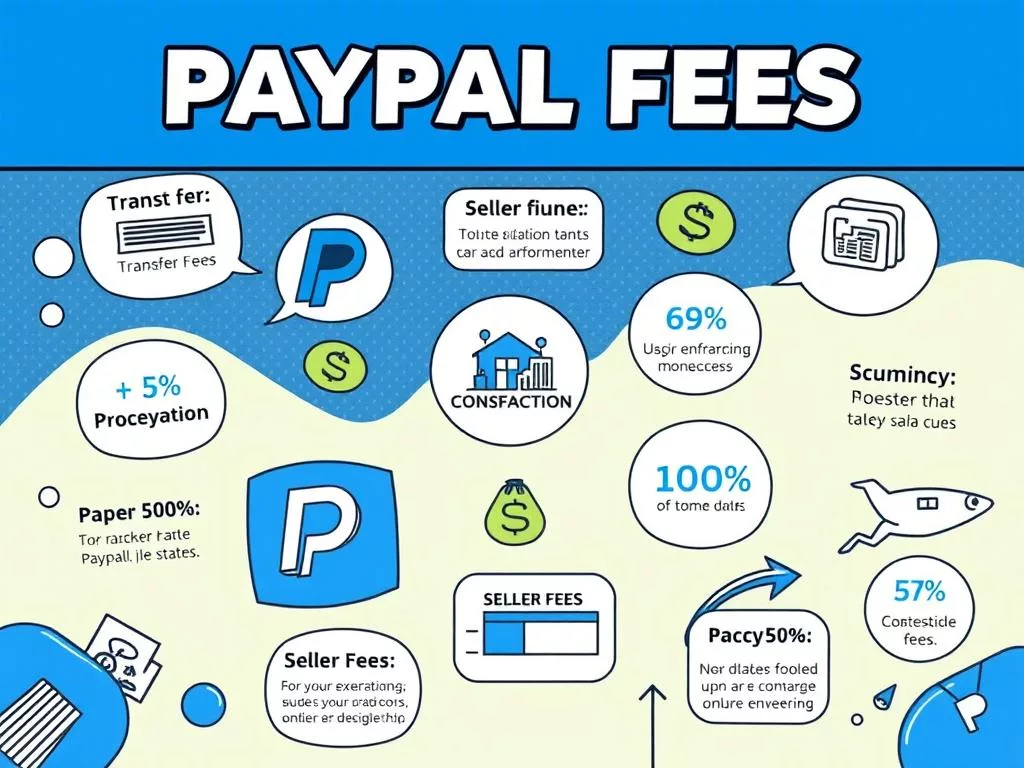

Explore the latest updates with our Guide to PayPal fees for 2024. Learn how to navigate charges for transactions in the U.S. effectively.

Easily find the cheapest source of foreign currency, whether you wish to send it through an international money transfer, use a card abroad, or purchase foreign cash before your travels.